The Windmill - a brief history

Once it stopped working, the mill became increasingly dilapidated; it was damaged by fire, lost its sweeps and fantail, and gaping holes appeared in its wooden sides. By 1922, when the village realised they were likely to lose their mill altogether a Parish Meeting was called, and raised £400 for repairs, with one of their distinguished supporters being Hilaire Belloc, the writer. The repairs resulted in much of the internal machinery being removed, and the doors were bricked up.

The following year, the Marquess of Abergavenny, Lord of the Manor, granted a 99-year lease of the mill, and the Trustees agreed ‘not to alter or detract from the picturesque appearance of the mill, and to preserve the same as an object of interest to the inhabitants and visitors to Rottingdean and district’.

When Rottingdean was absorbed into Brighton Borough in 1928, the Corporation acquired the lease of the windmill from the Abergavenny estate. In 1929 the Mill was re-tarred and basic repairs carried out. In 1935 Fred Neve, the Heathfield millwright made the Mill weatherproof and safe for many years, the work being funded by Mr Yapp of Haywards Heath. It was strengthened sufficiently to take a new set of sweeps.

When the Rottingdean Preservation Society was formed in 1960, the Trusteeship of the mill was vested in the members of the Society, together with a full repairing lease. Between 1961 and 1965, further repairs were carried out, including timber treatment for beetle, and the base was re-tarred. Soon after, gales damaged the sweeps, the mill was struck by lightning, and in 1969, a steel framework was erected inside the mill, to stop it twisting and collapsing. The work, carried out by Ernest Hole and Son, cost £3,500. Fortunately the Society received a substantial bequest from Mr R A Caton at about that time to make this and future work possible.

In the 1980s, on the advice of the Society for the Protection of Ancient Buildings, the sweeps were removed, and the weight of the upper structure transferred onto the steel frame. From that time on virtually the whole of the mill was supported by the internal steelwork. Remarkably, the mill then withstood the 1987 hurricane without significant damage. Subsequent work required a considerable amount of oak, including the donation of an English oak tree by Lord March of Goodwood.

As part of a Millennium Project, the Preservation Society replaced the wooden timbers that form the foundation for the cant posts. Further work to weatherproof the cap, rebuild and replace internal posts, frames and feather-boarding was also carried out, the total cost to the Society being over £57,000. In 2003, the sweeps and stocks needed replacement, and this was supported by a grant from the Heritage Lottery Fund.

And work continues on this Grade 2 listed landmark here on Beacon Hill! The prevailing south-westerly winds on this exposed part of the South Downs means that the Mill needs constant attention and maintenance, and this continues to be carried out by the Rottingdean Heritage. So, well over 100 years since it last ground corn for the village, this mill still remains a landmark for all to see and enjoy

Additional material and images

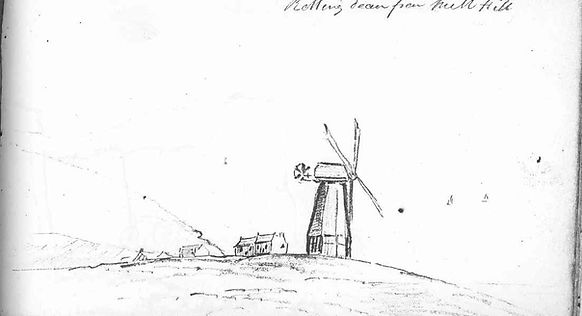

Rottingdean - Beacon Hill Smock Mill

By Mr Justin Brice

Notes extracted from the Simmons collection of records relating to British Windmills and Watermills, compiled by H.E.S. Simmons

Built in 1802 for Thomas Beard, she is a black smock mill on a Brick base. Her four patent sweeps drove 3 pairs of stones. Reputedly at one time the fan was painted red, white and blue (a Suffolk practice, this is only example heard of in Sussex). No evidence of a stage. There used to be a granary on the south side of the mill, the foundations of which were still discernible in the 1930s.

Sussex Weekly Advertiser, June 7th, 1802: “Describes the finding of a skeleton by the labourers who were digging the foundations for a mill being erected for Mr T Beard at Rottingdean. Skeleton said to be doubtless that of some ancient warrior, as his sword was lying parallel with his thigh bones”. By the time they’d returned from a tea break the relics had disappeared.

Norie’s Chart 1816 “from the latest surveys”. The Downs to Spithead. Names New and Old Mills at Rottingdean.

Sussex Weekly Advertiser, March 20th, 1849: “Stealing rope from a mill. John Mockford, a labourer, was brought up in custody, on charge of stealing several yards of rope, the property of Mr Charles Beard of Rottingdean. John Bodle deposed that he was miller in the service of Mr Beard…”.

This mill, like the smock mill at West Blatchington, was reputedly used by smugglers for signalling.

Sussex Advertiser, July 9th 1862: “Child killed by a windmill. A little boy, named Henry Smith, seven years of age, went to stay with his grandmother at Rottingdean. On Saturday afternoon (July 5th) he went in a mill there, where his uncle, a miller, was at work. For some time he was playing about with a little girl: later in the afternoon the miller heard a jerk in the mill, went out, and found the deceased lying insensible close under the sweeps, which at one part are only three feet from the ground. No one saw the accident occur. The poor child was at once taken to the County Hospital, where he died about 12 hours after admission”.

Charles Beard of Rottingdean, died 21st February 1870.

Sussex Advertiser, June 26th 1877: “Windmill to Let, at Rottingdean, driving three pairs of stones etc Rent £40 with cottage etc. Coal trade attached. Apply to Mr George Nicholls, Rottingdean”.

George Nicholls’ miller at Rottingdean was one named Ned Avery, an old man who in the days of his youth was constantly employed at the mill.

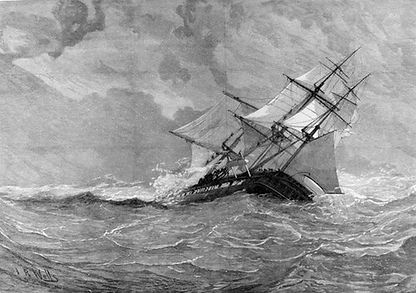

The sweeps were blown off in the great gale of 1879.

Last worked by Henry Nicholls in about 1889, but had ceased regular work in 1882. Nicholls in about 1886 went from Rottingdean to the Race Hill Mill, Brighton, which collapsed on the 16th May 1913. Nicholl’s miller at Rottingdean was a man named Neale. Henry Nicholls also succeeded George at Race Hill.

When milling activities at Rottingdean were brought to a close, it was decided to pull the mill down: but for some reason or other this was delayed, the mill in the meantime assuming a ruinous aspect until eventually it was patched up for the sake for appearance. A photo from about 1900 (left) shows it as being very dilapidated, with much of the weather-boarding stripped from its sides. In this condition it continued to stand for some years until eventually restored by the Marquis of Abergavenny, whose ground it stood upon, and its preservation was placed in the care of the parish.

An illustration in Country House, vol 3, 1910, depicts Rottingdean Mill as it later appeared, with the caption “Rottingdean was repaired by the Marquis of Abergavenny”.

In 1922, however, when showing signs of decay, destruction again threatened the mill, and some inhabitants even insisted that it should be demolished, but the Rev Lewis Verey, Vicar of Rottingdean at the time, was instrumental in raising sufficient money to safeguard its preservation, the site it occupied being leased for 99 years from the Brighton Corporation, who recently had acquired the surrounding land: and Mr Verey and three local residents were appointed Trustees, with whom all responsibilities remained.

Brighton & Hove Herald, 29th June 1935: “Brighton Council Meeting – June 27th. Restoration of Rottingdean Windmill. Sir George Lewis has written to the Corporation stating that he and three other gentlemen hold a lease of the Rottingdean Windmill, and that a gentleman, who wishes at present to remain anonymous, has made an offer to expend a considerable sum on putting the windmill into good condition and restoring the sweeps, thereby giving the mill its old appearance. The Council gladly gave formal sanction to these alterations”.

Restored in 1936 by Mr J Yapp, Beech Hurst, Haywards Heath. Boarding etc by K Gordon, builder and decorator, Broad Oak, Heathfield. Millwrighting effects by Fred Neve & Son, Heathfield. Sweeps by Holmans, of Canterbury. These “sweeps” (frames only) were fitted July 13th/14th, 1936.

An amateur newsreel style film by FJ Williams repairs carried out in 1936 can be viewed on the EUscreen.eu website. (See above).

H.E.S. Simmons presumably writing in the 1970s noted: “Unfortunately, with the exception of a short period during which the restorations of 1936 were being conducted, the mill has been sealed up for many years, and an inspection of the interior has, therefore, not been possible, but Mr Powell, the last miller of Shipley, who first became associated with windmills at Rottingdean, having assisted in the mill there as a lad, says he has always understood mill contains, or did contain, several features of more than usual interest. Says not a very roomy mill. Mr Powell went to school in Rottingdean. Used to go up to the mill after school to hang sack on”.

“Rottingdean, last Restored in December 1966 by Messrs Leslie Boutup and Mr Walter Buss Of Heathfield. In the January 1967 issue of Sussex Life is a photograph of the interior of the mill. Shows a wooden upright shaft, an 8 or nine spoked wheel and an almost solid wood wallower”.

Simmons also adds: “It is definitely stated in the Sussex Weekly Advertiser of June 1802 that labourers were then digging the foundations for a mill to be erected by Mr Beard at Rottingdean, and the Defence Schedules are said to have been completed in 1801. And yet in the latter there are two entries under Rottingdean, the first being for ‘Thomas Beard at The Mill, no cloth, a Smock Windmill on the Beacon Hill’ who was willing to supply own wheat ‘for ready money or on a month’s credit’. The Rottingdean Smock Mill could not have been completed before August or September of 1802, and in view of this it seems probable that although the schedules may have been begun in 1801, they were not completed that year. Had the mill been a post it could be accepted that a brick roundhouse was being added after the erection of the mill, but, in the case of a smock the base would have to be built first. (JB – unless the smock mill was originally built wood to the ground and was being raised onto a new brick base! Funnily enough there is an illustration of the mill which shows this!).

In c1969 a steel frame was fitted by Hole’s, the Burgess Hill Millwrights, to help her withstand the elements.

The local preservation society maintain her and they regularly open her to visitors.